DTF Supplies: Essential Tools for Successful Printing

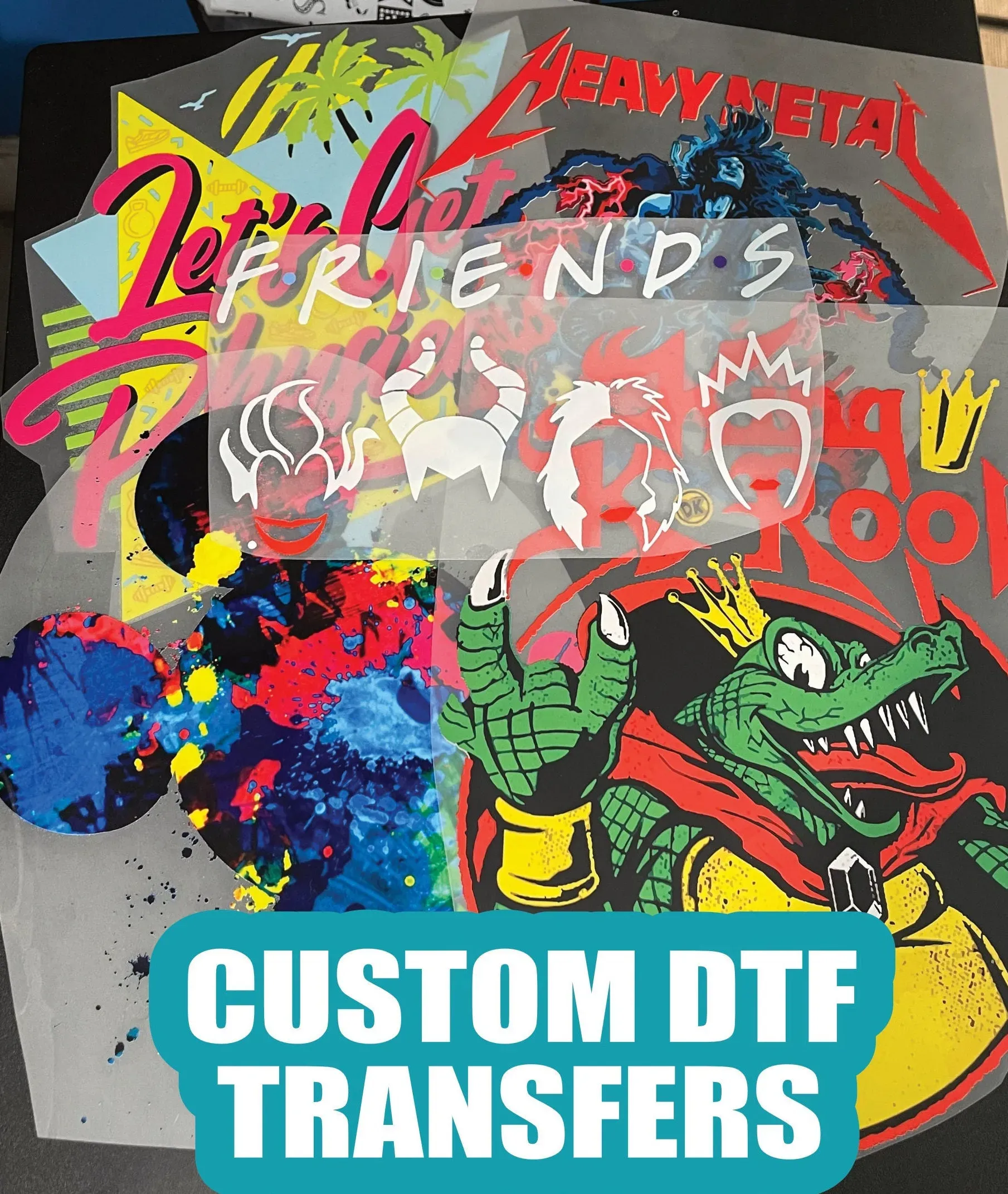

DTF supplies are essential for anyone looking to dive into the exciting world of Direct-to-Film (DTF) printing. This innovative printing technique allows creators from all backgrounds to produce vibrant, high-quality prints on textiles with relative ease. Whether you’re a professional looking to streamline your production process or a hobbyist eager to explore new creative avenues, having the right DTF printer, ink, transfer film, and additional supplies is crucial. In this guide, we’ll unravel what you need to get started with DTF printing and how each component works together to make your designs come to life. From premium DTF inks that ensure bright colors to precision heat presses that guarantee flawless application, equipping yourself with quality materials is the first step toward thriving in this dynamic field.

Exploring DTF materials is an exciting journey for both craft enthusiasts and professionals alike. Direct-to-Film methods have transformed the printing landscape, making it accessible and practical for custom garment decoration. Learning about the required tools such as specialized printers, transfer sheets, and unique adhesives provides a strong foundation for achieving smashing results. As this process gains popularity, understanding the nuances of each component—from the type of DTF inks used to the different techniques available—will enhance your printing experience. The growing range of DTF options also invites creativity, allowing for diverse textile applications that truly stand out.

Understanding the Importance of DTF Supplies

In the world of DTF printing, the importance of having the right supplies cannot be overstated. DTF supplies are specifically designed to work in harmony to produce outstanding prints on a range of fabrics. From the specialized DTF printer that ensures precise ink application to the DTF transfer film that captures intricate designs, each component plays a critical role in the final outcome. Without quality supplies, even the best designs can suffer, resulting in faded colors and poor adhesion.

Choosing the right DTF supplies can significantly enhance the quality of your prints. High-quality DTF inks are formulated to provide vibrant colors and strong adhesion to various textiles, while compatible transfer films act as the bridge that transfers your designs effectively. Starting with the right supplies gives beginners the confidence to experiment with their creativity, ultimately leading to consistent, high-quality results.

Key Components of DTF Printing

DTF printing encompasses several key components that contribute to the process, each vital for achieving professional results. The DTF printer itself is designed to handle unique DTF inks that differ from conventional printing inks. This precision is critical to ensuring that colors pop and details remain crisp. Understanding the nuances of your DTF printer and its compatible inks allows for better control over the printing process, enhancing creativity without limitations.

Additionally, the choice of transfer film in DTF printing can greatly influence the quality of the finished product. Films that are too thin may struggle to transfer intricate designs, while overly thick films can lead to unwanted texture on the final print. Experimenting with various types of DTF transfer films can help users identify which works best for their specific needs, thereby refining their overall printing technique and results.

Choosing the Right DTF Printer

Selecting the right DTF printer is a crucial step for anyone interested in starting their DTF printing journey. Printers designed specifically for DTF operations, like certain models from Epson, are optimized to handle the complexities of DTF inks, producing clearer and more vibrant images. These printers incorporate advanced technology, ensuring efficient ink distribution and preventing clogs that can often occur with standard printers, saving time and materials.

When considering a DTF printer, it’s also important to assess the scalability of your printing endeavors. Many businesses start small and expand into larger operations; hence, investing in a reliable DTF printer that can handle increased workloads can pay off in the long run. Look for features such as print speed, width capacity, and user-friendliness to ensure that your choice aligns well with future growth.

The Role of DTF Transfer Film

DTF transfer film is more than just a surface; it is the gateway for transferring designs onto fabrics effectively. The choice of transfer film can significantly affect print accuracy and durability, making it a vital supply in the DTF printing process. High-quality films allow for the preservation of vibrant colors and intricate details, essential for businesses that depend on presenting an attractive product. Testing various films can be beneficial to find the ideal match for your specific printing needs.

Moreover, using compatible transfer films speeds up the printing process by ensuring seamless adhesion. Different films are designed for various textile types, and understanding which film works best for your projects can lead to greater efficiency in production. Learning how each film behaves during heat application will eventually lead to fewer errors and a more polished final product.

The Importance of DTF Ink Quality

DTF ink is a fundamental component in achieving the best results in your printing projects. The quality of DTF ink directly affects color vibrancy, wash durability, and adhesion to fabric. Low-quality inks may save money initially but can lead to faded or peeling prints after a few washes. It is always advisable to invest in DTF inks from reputable suppliers, as they are specifically formulated to work synergistically with transfer films and printers, enhancing overall print quality.

Furthermore, the formulation of DTF inks often incorporates advanced ingredients that enable better penetration into fabric fibers, leading to long-lasting results. Users should also pay attention to the ink’s compatibility with their specific DTF printer to prevent clogs and maintain consistent output. Understanding these aspects of DTF ink empowers users to produce professional-grade prints that stand the test of time and usage.

Investing in Reliable Heat Press Machines

The heat press machine is a vital supply that acts as the final step for DTF printing. Investing in a reliable heat press not only enhances your ability to transfer prints onto garments effectively but also ensures professional quality in every application. With adjustable settings for temperature and pressure, you can tailor your method to various fabric types, achieving optimal results. A well-functioning heat press is an investment that pays off, allowing for consistent and high-quality print applications across projects.

Moreover, the choice of heat press also matters for time efficiency in a production environment. Heat presses with digital interfaces, auto-release features, or multi-function capabilities can significantly increase your workflow, reducing the time spent on each application and enhancing productivity. Understanding how to utilize and maintain your heat press effectively will further enhance your DTF printing experience.

Frequently Asked Questions

What are the essential DTF supplies for beginners?

For beginners in DTF printing, essential supplies include a dedicated DTF printer, high-quality DTF transfer film, DTF ink, hot melt powder for adhesion, a reliable heat press machine, and cutting tools like vinyl cutters. These components are crucial for producing vibrant and durable prints.

How does DTF printing differ from traditional screen printing?

DTF printing differs from traditional screen printing in its process and versatility. While screen printing requires multiple screens for different colors, DTF prints images directly onto transfer film, which can then be applied to various fabrics. This method allows for more intricate designs and is more cost-effective for small runs.

Can I use any ink with a DTF printer?

No, using standard ink in a DTF printer is not advisable. DTF printers require specialized DTF ink, formulated for strong adhesion and vibrancy. Using the correct ink optimizes print quality and durability on textiles, ensuring successful application.

What types of fabrics can I use with DTF printing?

DTF printing is highly versatile and can be used on a variety of fabrics, including cotton, polyester, and fabric blends. This adaptability makes it a popular choice among clothing brands and DIY enthusiasts looking to produce custom garments.

How does hot melt powder work in DTF printing?

Hot melt powder plays a critical role in DTF printing by acting as an adhesive when applying prints to fabric. After printing on the transfer film, the powder is sprinkled over the design and heated. This melting process bonds the ink to the fabric, resulting in long-lasting prints.

Are there specific cutting tools recommended for DTF printing?

Yes, specific cutting tools such as vinyl cutters are highly recommended for DTF printing. These tools help accurately trim printed transfers to fit various fabric types and projects, improving accuracy and minimizing waste during the printing process.

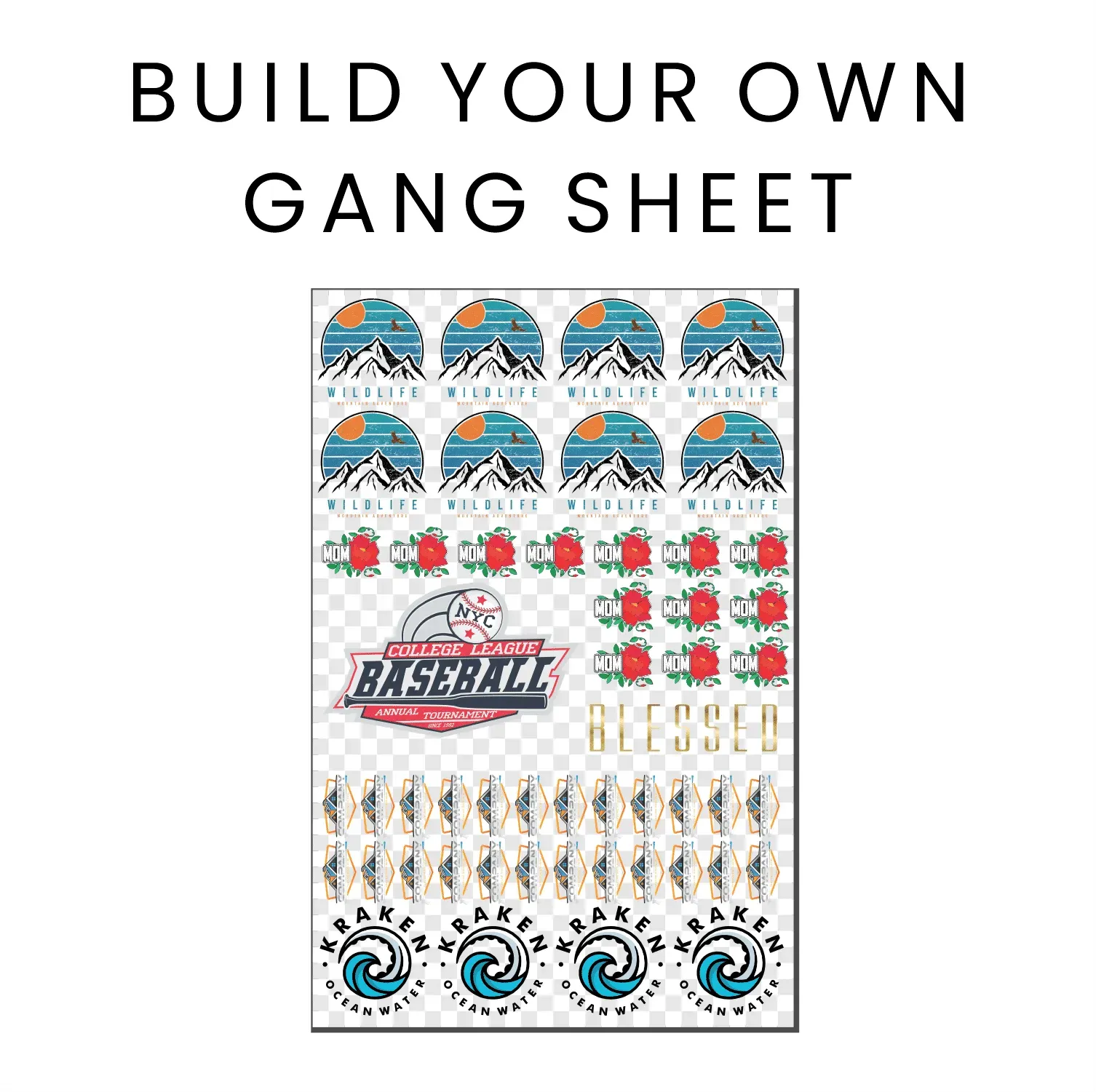

| Supply | Description |

|---|---|

| DTF Printer | Specialized printers designed for DTF inks and films, ensuring high-quality prints. |

| Transfer Film | A special film used to print designs that must be compatible with the printer for quality. |

| DTF Ink | Specially formulated ink providing strong adhesion and durability when transferred to fabric. |

| Hot Melt Powder | Adhesive powder used to bond printed designs to fabric during the heat press process. |

| Heat Press Machine | A machine used to apply heat and pressure to transfer prints onto fabric. |

| Cutting Tools | Tools like vinyl cutters that allow for precise trimming of printed transfers. |

Summary

DTF supplies are essential for anyone looking to excel in the realm of Direct-to-Film printing. This printing technique not only offers versatility but also empowers artists and businesses alike to create stunning designs on various fabrics. By mastering the necessary DTF supplies, such as printers, transfer films, special inks, hot melt powders, heat presses, and cutting tools, you are equipped to produce vibrant, durable prints that can stand the test of time. With new advancements and a supportive community, now is an opportune moment to dive into DTF printing and unleash your creativity.